#Automatic Flexo Printing Machine

Explore tagged Tumblr posts

Text

Why Manufacturers Prefer Woven Sack Bag to Bag Flexo Printing Machines Today

In today’s fast-paced packaging industry, the demand for high-quality, durable, and visually appealing woven sacks is rapidly growing. One of the key technologies that has revolutionized this sector is the Woven Sack Bag to Bag Flexo Printing Machine. These machines are preferred by manufacturers across the globe due to their ability to deliver precision printing, high-speed output, and cost efficiency.

In this blog, we will explore why these machines are becoming the go-to choice for modern manufacturers, what benefits they offer, and why Gabbar Industries is considered the best manufacturer of Woven Sack Bag to Bag Flexo Printing Machines in India.

What is a Woven Sack Bag to Bag Flexo Printing Machine?

A Woven Sack Bag to Bag Flexo Printing Machine is a high-performance printing solution designed specifically for printing on pre-stitched or finished woven sacks. Unlike traditional roll-to-roll machines, these systems allow manufacturers to print directly on individual bags with high accuracy and clarity.

Flexographic printing uses flexible relief plates to transfer ink onto the substrate. In the case of woven sacks, this method ensures quick-drying, low-cost, and efficient printing for various applications including fertilizers, cement, food grains, sugar, chemicals, and more.

Why Are Manufacturers Switching to Flexo Printing Machines?

Here are the top reasons manufacturers are increasingly preferring Woven Sack Bag to Bag Flexo Printing Machines:

1. High-Speed Performance

Modern flexo machines are capable of printing thousands of bags per hour. With automation and efficient bag feeding systems, production speed sees a significant boost — saving time and increasing overall output.

2. Superior Print Quality

One of the biggest advantages of a flexo printing machine is its ability to provide sharp, consistent, and smudge-free prints. Manufacturers can rely on the machine to deliver high-resolution branding, logos, and product information that enhances the packaging’s professional look.

3. Cost Efficiency

Compared to traditional printing methods, flexographic printing is more economical in the long run. With quick setup times, minimal waste, and low ink consumption, manufacturers save significantly on operational costs.

4. Flexibility in Design and Ink Compatibility

Flexo printing supports a wide range of inks including water-based, solvent-based, and UV curable inks. This makes it easier for manufacturers to adapt to different client requirements and industries.

5. Eco-Friendly Operation

With increased focus on sustainability, manufacturers are choosing Woven Sack Bag to Bag Flexo Printing Machines that support water-based inks and low energy consumption. This helps companies meet environmental standards while maintaining product quality.

6. User-Friendly Automation and Controls

Modern flexo machines come equipped with advanced PLC controls, touch screens, and automatic tension control. These features reduce human error, minimize downtime, and ensure smooth operation for operators.

7. Customization and Versatility

Manufacturers can choose from various configurations — ranging from 2-color to 8-color machines — depending on their production needs. Flexo machines can handle different bag sizes and thicknesses, offering the flexibility needed for diverse production lines.

8. Durability and Low Maintenance

A major reason for preferring flexo printing machines is their robust construction and long service life. With proper maintenance, these machines can operate for years without major breakdowns, reducing overall downtime and maintenance costs.

Industries That Benefit from Flexo Printing on Woven Sacks

Agriculture: For packaging seeds, grains, fertilizers

Cement & Construction: Durable printing on cement bags

Chemical: Leak-proof printing on chemical packaging

Food Industry: Branded bags for sugar, flour, rice, etc.

Retail & Wholesale: Custom-printed sacks for bulk packaging

Why Choose Gabbar Industries?

When it comes to investing in a high-quality Woven Sack Bag to Bag Flexo Printing Machine, choosing the right manufacturer is crucial. This is where Gabbar Industries stands out.

Trusted Experience

With years of experience in machinery manufacturing, Gabbar Industries is known for delivering reliable and innovative printing solutions.

Superior Engineering

Every machine is built using high-grade materials, precision components, and tested for optimal performance.

Customization Options

Gabbar Industries provides machines tailored to your specific production requirements, from basic to advanced models.

️ After-Sales Support

From installation to maintenance, their dedicated support team ensures your machine continues to deliver peak performance.

Get in Touch with Gabbar Industries

Interested in upgrading your production line with a high-speed, cost-effective Woven Sack Bag to Bag Flexo Printing Machine?

Conclusion

The demand for superior packaging is only increasing, and manufacturers must stay ahead by investing in the right technology. A Woven Sack Bag to Bag Flexo Printing Machine is a smart investment for anyone looking to boost production, ensure quality, and cut down operational costs.

Gabbar Industries is the name you can trust when it comes to robust, efficient, and innovative printing solutions. Don’t settle for less — upgrade your woven sack printing capabilities today!

📞 Contact: (+91) 9879039000 🌐 Website: https://gabbarindustries.com/

0 notes

Text

How to Choose the Right Flexo Printing Machinery

Investing in the right flexographic (flexo) printing machine is an important decision for any printing or packaging business. The right equipment can improve print quality, speed up production, and reduce operating costs. However, with many options available in the market, choosing the right machine can be challenging.

In this blog, we’ll help you understand what to look for when selecting a flexo printing machine. Whether you're a startup or an established business, working with experienced flexo printing machine manufacturers and choosing a trusted printing machine manufacturer in India can make a big difference.

Understand Your Business Needs

Before you start comparing machines, it's important to know what you need. Consider the type of material you plan to print on—paper, plastic, film, foil, or labels. Also, think about your production volume, color requirements, and the level of automation you need. If your jobs involve short runs with frequent changes, you’ll need a machine that allows quick setup and easy plate changes.

Look for Print Quality and Speed

Flexo printing machines are known for high-speed printing, but print quality should never be compromised. Choose a machine that offers sharp image clarity and consistent ink distribution. A good machine should balance speed and quality to help you meet deadlines without sacrificing output.

Evaluate Machine Features and Technology

Modern flexo machines come with advanced features like automatic tension control, drying systems, and computer-based controls. These features reduce manual work and increase efficiency. Machines with servo drives and automatic registration systems help improve precision and reduce material waste.

When choosing a machine, look for features that match your workflow and production goals. It’s best to select a machine that offers room for upgrades or customization if your needs grow in the future.

Consider After-Sales Support and Maintenance

Even the best machine will require maintenance over time. That’s why after-sales support is crucial. Work with flexo printing machine manufacturers that offer training, spare parts, technical guidance, and quick service response. This will help reduce downtime and keep your production running smoothly.

Choose the Right Manufacturer

Partnering with a reliable printing machine manufacturer in India ensures that you receive a machine that’s built to last. Look for manufacturers with proven experience, good client reviews, and a strong focus on quality. Companies like NBG Printographic Machinery Co. Pvt. Ltd. have decades of experience and offer advanced flexo printing solutions for various printing needs. Their machines are built with precision, using modern technology and durable materials, making them a preferred choice for clients in India and abroad.

Plan Your Budget Wisely

Cost is always a factor, but it's important to focus on value—not just price. A cheaper machine might cost more in the long run due to breakdowns, poor print quality, or limited features. On the other hand, a well-designed, efficient machine might offer faster returns through increased productivity and lower maintenance costs.

Ask the manufacturer about total cost of ownership, including installation, training, spare parts, and support.

Final Thoughts

Choosing the right flexo printing machinery takes careful planning and research. Understand your needs, compare machine features, and work with a trusted printing machine manufacturer in India who offers long-term value and support.

Flexo printing is a smart investment for packaging and label production, but the success of that investment depends on the machine you choose. Reliable flexo printing machine manufacturers can help you find the perfect fit for your business—improving quality, efficiency, and profitability.

Ready to take the next step? Explore the latest flexo printing machines at NBG Printographic Machinery Co. Pvt. Ltd. and find the perfect solution for your printing needs.

0 notes

Text

Exploring the World of Non-Woven Shopping Bag Manufacturers

As the world leans into sustainability and eco-conscious choices, non-woven shopping bags have emerged as a smart alternative to single-use plastic bags. Durable, reusable, and easy on the environment, these bags are gaining popularity across industries—from retail stores and supermarkets to promotional events and giveaways.

But ever wondered how these bags are made and who’s behind their production? Let’s take a friendly deep dive into the fascinating world of non-woven shopping bag manufacturers.

🌿 What Are Non-Woven Bags?

Non-woven bags are made using a fabric-like material created from long fibers, bonded together through chemical, mechanical, heat, or solvent treatment. Unlike woven materials, non-woven fabrics don’t require weaving or knitting, making them quicker and more cost-effective to produce.

Key Features:

Lightweight yet strong

Water-resistant

Recyclable and reusable

Customizable for branding

These features make non-woven bags a popular choice for businesses looking to promote sustainability without compromising on style or function.

🏭 Inside a Non-Woven Bag Manufacturing Unit

A non-woven shopping bag manufacturer typically operates in a facility equipped with advanced machinery designed for mass production with precision. Here’s how the process usually unfolds:

1. Raw Material Preparation

Polypropylene granules are melted and spun into threads, which are then pressed into sheets of non-woven fabric.

2. Printing and Branding

Using methods like screen printing, heat transfer, or flexo printing, custom logos and designs are added. This stage is especially important for promotional and retail businesses.

3. Cutting and Stitching

Fabric sheets are cut into desired sizes and shapes. Automatic or semi-automatic machines handle ultrasonic stitching or heat sealing, depending on the bag style.

4. Quality Check and Packaging

Each batch goes through quality inspections to ensure durability and finish before being packed and dispatched.

🔍 What to Look for in a Non-Woven Bag Manufacturer

Choosing the right manufacturer can make all the difference in terms of quality, pricing, and delivery. Here are some factors to consider:

Experience and Reputation Go for manufacturers who have a track record of reliability and consistent quality.

Customization Options Look for flexibility in colors, sizes, printing techniques, and bag styles (D-cut, box type, loop handle, etc.)

Minimum Order Quantity (MOQ) Some cater to bulk orders only, while others are more startup-friendly.

Sustainability Practices A commitment to eco-friendly materials and waste management is a big plus.

Delivery and Support Timely dispatch and responsive customer service reflect a professional setup.

📦 Why Businesses Love Non-Woven Bags

From small local stores to large retail chains, businesses are switching to non-woven bags for good reasons:

Cost-effective marketing tool

Enhances brand image

Complies with plastic bans and eco-regulations

Long shelf life with repeat brand exposure

Final Thoughts

Non-woven shopping bag manufacturers play a vital role in shaping a more sustainable future. By offering practical, reusable alternatives to plastic bags, they help businesses and individuals reduce their environmental impact—one bag at a time.

Whether you’re a business owner looking for eco-friendly packaging or someone simply curious about sustainable trends, understanding the backbone of non-woven bag production gives a whole new appreciation for that sturdy tote you carry every day.

0 notes

Text

Spinaroo Commercial IPO: Price, GMP, And Date

SME IPO

Spinaroo Commercial IPO-Complete Overview

Spinaroo Commercial IPO under the SME IPO category is a fixed price issue of Rs.10.17 Cr by Spinaroo Commercial Limited which was incorporated on August 17, 2012. The company has been involved with lots in the manufacture of aluminum foil containers, aluminum home foil, paper cups, paper plates, and paper bowls, along with semi-prepared materials for paper cups, mainly paper coating, printing, and blanking.

These comprise a whole array of additional machinery for paper cups examples are high-speed paper cup-making machines, flexo printing machines, and automatic roll die-cutting machines. Thus, they offer full-blown end-to-end support.

The company has in stock numerous high-quality products manufactured from super-quality raw materials, which are ensured under expert guidance and intervention, into premier-performing but competitively priced, timely deliveries made to the specifications of clients.

Business Segment

Manufacturing: It manufactures aluminum home foil and containers. Uses quality-based materials to produce items, such as cups, plates, and bowls, all under the paper products category meant for food. Also sells semi-finished raw materials processed and modified.

Trading: It produces aluminum foils and containers, as well as paper products such as high-quality, food-grade materials from which it obtains semi-finished raw materials intended for paper cups, plates, and bowls after appropriate processing and modification.

Job Work: The specific job work services offered by this company are processing, shaping, and printing on paper products. The coating applied is also to the customer's specification using food-grade materials.

1 note

·

View note

Text

Paper Cup-Making Machine in Delhi NCR

Over the past few years, the packaging industry has undergone tremendous changes, as people have increasingly sought to switch to green alternatives. One such innovation that has revolutionized the beverage and food packaging industry is the paper cup-making machine. These machines have become a necessity in manufacturing high-quality, sustainable paper cups for fast food restaurants, event catering services, and others.

As businesses in cities like Delhi, Noida, Gurgaon, and surrounding areas strive to reduce their environmental footprint, the demand for paper cups has surged, alongside the need for efficient and reliable manufacturing processes. In this blog, we’ll delve into how paper cup-making machines are revolutionizing the industry and why they are a game-changer for businesses in Delhi and beyond.

The Growing Demand for Paper Cups

As a result of this global trend toward sustainable packaging, paper cups are fast becoming a more popular option compared to plastic cups. Paper cups are biodegradable and recyclable and come from renewable resources, so they are more environmentally friendly to use both by consumers and companies.

Paper cups have become in great demand in Delhi, Noida, Gurgaon, and surrounding areas due to increased environmental awareness and stringent rules on plastic usage. This demand has led manufacturers to invest in paper cup-making machines to meet the growing demands of the food and beverage industry.

Benefits of Paper Cup-Making Machines

1. Sustainability

The most important advantage of paper cup-making machines is that they produce eco-friendly products. The use of renewable materials like paperboard, ensuring that paper cups are biodegradable, reduces the impact of businesses on the environment. This is very important in cities like Delhi, where plastic waste and pollution have become a major concern.

With paper cup-making machines, manufacturers can produce high volumes of paper cups with minimal waste, thus making the production process more sustainable and efficient.

2. High-Speed Production

Speed and efficiency are very important in the fast world of food and beverage services. Paper cup-making machines are designed to work at a high speed to produce thousands of cups in a short time. This makes them ideal for high-volume production environments in Delhi, Noida, Gurgaon, and surrounding regions where demand for paper cups is high.

These machines are furnished with automatic controls and high technology, which provides for continuous and smooth production without any downtime; hence it is enhanced in terms of productivity.

3. Customization

Modern paper cup-making machines offer the flexibility of many variants in design options. Be it the size, shape, or design of the paper cups, the versatility of machines offered at reasonable prices to manufacturers helps cater to the specific needs of customers. This is highly desirable for businesses operating in highly competitive markets such as Delhi and Gurgaon.

Custom branding is the most popular in the food and beverage industry, where companies use branded paper cups to market their brands. The machine can hold a variety of printing options, including flexo and offset printing, to guarantee the most colorful and high-quality designs.

4. Cost-Effectiveness

While the initial investment in paper cup-making machines seems huge, they help in saving long-term costs through efficient production. The mass production of quality cups in a short period reduces labor and material costs. Additionally, the high-speed production capability helps businesses in Delhi and surrounding areas meet demand without compromising on quality.

5. Consistency and Quality

Manual manufacturing of paper cups results in a variable size, shape, and quality. Paper cup-making machines, on the other hand, produce each cup with precision to ensure uniformity and consistent quality. The high technology involved in these machines minimizes human error, and quality control measures are incorporated into the production line to ensure that only the best quality reaches the market.

Key Features of Paper Cup-Making Machines

When choosing a paper cup-making machine, businesses operating in Delhi, Noida, Gurgaon, and surrounding areas need to look out for the following key features that will enhance production:

1. Advanced Automation

The paper cup-making machine of today is very automated, hence, it cuts down on human interference and produces a better quality output. In automated systems, there is more accuracy in forming the cup; therefore, an appropriate amount of material is consumed in each unit.

2. Durability

Given the high-volume production environment, durability is a critical feature. Paper cup-making machines are designed to withstand continuous use in production facilities. The use of high-quality materials ensures the machines last for years, offering a solid return on investment.

3. Energy Efficiency

Energy-efficient machines help reduce operation costs, especially for businesses that involve high-scale productions. Paper cup-making machines designed with energy efficiency capabilities can limit electricity consumption even when performance levels are maintained and will be quite appropriate for producers in Delhi and Gurgaon.

4. Flexible Production Capabilities

Some of the high-tech machines can make various sizes of paper cups, from espresso to large beverage cups. Flexibility in the size of production is essential for businesses catering to different needs of customers in the food service or event management industry.

5. Ease of Operation

User-friendly interfaces and easy-to-understand controls are essential for smooth running. Machines are designed to check human error minimally by making the production process as simple as possible. The training for the operators is minimal, and thus businesses in Noida and Delhi can hit the ground running.

The Role of Paper Cup-Making Machines in Sustainable Packaging

Sustainability is the buzzword in today’s packaging revolution, and paper cup-making machines are crucial in helping businesses adopt green practices. Consumers and businesses are now looking for biodegradable and recyclable packaging materials because of the increasing awareness of the impact of plastic waste on the environment.

It is, therefore, the most responsible and effective decision for areas such as Delhi, where pollution levels are so high that they impact the environment significantly. With the invention of paper cup-making machines, companies can now cater to the need for sustainable packaging without compromising on quality or efficiency.

Large volumes of eco-friendly paper cups produced also help businesses comply with local regulations concerning plastic usage. The Indian government has put various bans and restrictions on single-use plastics, so the adoption of paper cups has become imperative for businesses in Delhi, Gurgaon, and Noida.

Why Choose Paper Cup-Making Machines in Delhi and Nearby Areas?

1. Proximity to Major Markets

Some of India’s largest and most influential food and beverage businesses are found in Delhi, Noida, Gurgaon, and other nearby cities. Manufacturers can easily meet the growing demand for eco-friendly cups from these major markets by investing in paper cup-making machines.

2. Support for Green Initiatives

The Delhi government, along with other local authorities, is now actively promoting sustainable manufacturing practices. Paper cup-making machines allow businesses to meet these green goals, enjoy tax benefits, and be seen as environmentally friendly organizations.

3. Availability of Skilled Labor

Delhi, Noida, and Gurgaon are places where skilled labor is available. Thus, making the operation of paper cup-making machines easier for the manufacturers. The local technicians and operators know how to keep the machine up and running without extended downtime for the businesses.

Conclusion

Paper cup-making machines are revolutionizing the packaging industry by providing businesses in Delhi, Noida, Gurgaon, and beyond with a sustainable, efficient, and cost-effective solution for packaging beverages. These machines not only respond to the growing demand for green products but also improve production efficiency, cut costs, and enhance brand image. With increasing environmental concerns, the use of paper cup-making machines is a step in the right direction towards finding more sustainable and responsible packaging solutions.

FAQs

Q1: Can paper cup-making machines produce different sizes of cups?Yes, modern paper cup-making machines are capable of producing various sizes of cups, from small espresso cups to larger beverage cups, depending on the business’s requirements.

Q2: Are paper cups made from these machines biodegradable?Yes, paper cups produced by paper cup-making machines are biodegradable, making them a sustainable alternative to plastic cups.

Q3: How fast can a paper cup-making machine produce cups?Depending on the machine’s model, it can produce several thousand cups per hour, making it ideal for high-volume production environments.

Q4: Is maintenance expensive for paper cup-making machines?Maintenance costs are relatively low for paper cup-making machines, especially if they are regularly serviced by skilled technicians in Delhi, Noida, or Gurgaon.

Q5: Can I print custom designs on paper cups?Yes, paper cup-making machines allow for custom branding and printing, enabling businesses to design cups with their logos or special designs.

0 notes

Text

UV Coating Machine | Automatic UV Coating Machine

EMBELLISHMENT & UV COATING MACHINE

Different types for UV and Aqueous coating like Spot / Spot Not Coating, Flood Coating, Aqueous Coating, Blister Coating, Texture Coating can be done in Fine Coat Series. “Precision spot coating with Drip Off effects” can be done in the “Twin Tower FC 80 Drip Off” machine. Coating thickness can be varied from 3 – 8 gsm. The Coating can be done on various types of substrates like Art Paper, Duplex Board, Chromo Art, Sticker Sheet, Cyber Excel Board and Metpet Sheet.

Our Autoprint fine coat series comprises of automatic UV coating machine such as: Autoprint fine coat 65, Autoprint fine coat 80, Autoprint fine coat 80 AX and Autoprint fine coat 80 Drip off.

Autoprint fine coat, an offline sheet fed UV and aqueous coating machine is one such revolutionary products from Autoprint. Autoprint Fine coat machines can perform full coat and spot (UV & aqueous) coating on thin and thick papers.

Autoprint’s automatic UV coating machine are designed to meet the growing demand for a reliable and precision coater for large format printer and packaging units. Autoprint’s automatic UV coating machine has single sheet feeder in Autoprint fine coat 65and steam feeder system in other Autoprint fine coat machines. Autoprint fine coat 80 drip off is a special series which has drip off in it.

Autoprint fine coat 80 drip off is an offline 2 tower automatic UV coating and aqueous coating machine that helps you to add value with high quality effect to your print jobs.

FINE COAT 80 - UV & AQUEOUS COATING MACHINE

Autoprint Fine Coat 80 is an offline sheetfed Flexo Rotary Automatic UV and Aqueous Coater with UV and IR Dryer. It can perform Full or Flood coating, Spot coating and Spot-not window coating of both UV based and water based coatings.

KNOW MORE

FINE COAT 80 AX - SPOT UV COATING MACHINE

Autoprint Fine Coat 80 AX is an offline sheetfed Flexo Rotary Automatic UV and Aqueous Coater with UV and IR Dryer. It can perform Full or Flood coating, Spot coating and Spot-not window coating of both UV based and water based coatings.

KNOW MORE

FINE COAT 80 - DRIP OFF UV COATING MACHINE

It is designed to meet the growing demand for a reliable and precision coater for large format printers and packaging units.Autoprint Fine Coat 80 Drip Off is an offline sheetfed Flexo Rotary Automatic UV and Aqueous Coater with UV and IR Dryer.

KNOW MORE

AUTOPRINT FINE COAT DRIP OFF 105- UV & AQUEOUS COATING MACHINE

Autoprint Fine Coat 105 Drip Off is an offline 2 tower UV and Aqueous coating machine that help you to add value to your print job and tap the growingpotential in this market segment. This machine is specially designed to give high quality special coating effect on printed products..

KNOW MORE

AUTOPRINT MINI UV COATER (20” X 30”)

The Autoprint Mini UV Coater is here to revolutionize the way you finish your prints. A mini UV coater is a compact device designed for applying a UV coating to printed materials. UV coating is a finishing technique that involves applying a clear liquid coating to a surface and then curing it with ultraviolet light.

KNOW MORE CONTACT US

Autoprint Machinery Mfrs Pvt. Ltd. Kaanchan, # 9, North Huzur Road, Coimbatore - 641 018, Tamilnadu, India.

Phone : (+91) 422 - 2212416, 4225444 Email : [email protected] Read More....

0 notes

Text

Lug Caps Manufacturers Suppliers In India

We have our units located in Site IV Sahibabad Industrial Area, Ghaziabad, UP (Delhi NCR) with a consolidated covered working space of more than 30 thousand square feet. We are well equipped and with all the amenities rendered by UPSIDC. Our units are very well connected to all type of transportations lug caps manufacturers suppliers in india .

We manufacture : .

LUG CAPS in various sizes and colours.

RO CAPS in all sizes & gauges.

SELF ADHESIVE LABELS upto eight colour printing in roll or sheet form.

WETGLUE LABELS of various sizes and colour to cater all types of packaging modes.

ROPP CAPS in different sizes for pharma, distilleries, or all bottle packaging.

PARMESHTHI Enterprises manufactures self-adhesive labels and wet glue labels for variety of bottled or canned products. It also manufactures pp caps for glass or plastic bottles.

In unit 2 plant, the lug caps and dop Caps are also manufactured of various sizes to cater the needs of the customer.

The plant is situated at a very good location and easy approachable by road at Site IV in the Sahibabad industrial area with all amenities provided by lug caps exporters in india.

It is a team of high skilled technical experts, designers and professionals, continuously pouring the essence of their talent and endeavours, delivering the fine quality in large quantity of multi -colour labels.

The processing and production is operational under a 15000sft covered area, equipped with electric generator for an uninterrupted productivity. The sensitive areas are dust proof and air-conditioned.

Added to other machines, it has a fully loaded multicolor LED flexo printing press, first of its kind in India, delivering cost effective and high-quality labels. It drives out 40 thousand meters per day, of printed rolls. The company has its own brand of paper/stock for its labels to challenge the quality, durability, colour stability, gloss and finish of its labels.

The automatic electronic cutters are tuned to recognize and slice the contiguous borders in simple straight line or designer cut finish.

A team of experts equipped with scanners shuffle the production for its continuous integration to table it for packing and dispatch metal caps manufacturer delhi ncr .

P.ent remains its brand of stock, labels, caps.

Company has its own fleet of vehicles to manage the logistics and schedules of deliveries directly to the esteemed clients.Mr. Anuj Jain, the young and dynamic entrepreneur is behind the wheels, steering the organization to build its reputation in shape of reliability and product confidence.

0 notes

Text

Leo Flexipack fine-tunes print finishing with Rhyguan

An one-stop labelling solutions provider, Vapi-based Leo Flexipack has enhanced its digital finishing capabilities with the installation of a Rhyguan PLUS 330. This new highly modular Rhyguan digital finishing machine at Leo Flexipack’s facility has been supplied and installed by Flexo Image Graphics, a distributor & service provider of flexo presses & associated equipment in the Indian sub-continent.

The Rhyguan PLUS 330 has helped Leo Flexipack to fine-tune finishing into a new standard, the company said in a release. “A game changer indeed, this modular in design and fully servo-driven Rhyguan digital finishing system for embellishments from FIG, no doubt, has changed our overall efficiency in print finishing. It certainly works amazing in digital label finishing and such jobs,” says Hemant Dayama, CEO at Leo Flexipack.

He adds, “Since our inception in the year 2017, we have been closely partnered with FIG. In a way, we would say we keep going with a lot of products, support and admiration from FIG. We marked our beginning in our early days with a strategic investment in a Mark Andy P5 (Performance Series) flexo press from FIG. In addition to the machines, we are truly contented and satisfied with FIG’s unconditional support and co-operation.”

Some key machines now running productively at Leo Flexipack include a Mark Andy P5, HP Indigo 6K, and the new Rhyguan PLUS 330. Supported by a team of 50 plus printing and production professionals, the company is working for big bands from different sectors, such as FMCG, cosmetics, alcobev, etc. “With a special focus on the central & western India, we extensively work for our clients at pan-India level,” Dayama says.

He continues, “We keep expanding on all fronts, it would be either our machine portfolio or customer base. In this, we value constant investments in new machines such as the advanced Rhyguan PLUS 330, which we recently bought from FIG. Certainly, this Rhyguan PLUS digital finishing machine is ideally flexible and highly advanced to handle all crucial tasks with value-added embellishments.”

Some of the advanced features of Rhyguan PLUS 330 include its semi/full rotary die-cutting unit with Z204 magnetic cylinder, Z106 anvil & counter roller; 40T (optionally 60T) heavy duty embossing unit designed suitably for heaviest blind embossing jobs; an automatic suction box ensuring precision and stability of media; enough power for high-quality hot foiling, relief and micro-embossing—all in one step using 300x330/420mm tooling... and so on.

Like Leo Flexipack, a host of companies in India are satisfactorily running Rhyguan finishing machines supplied and installed by FIG. Along with Rhyguan and Mark Andy, FIG distributes an array of machines from other reputed international brands such as Rotoflex, Luster, Kluge, KDS Quantum, Presstek, etc. When it comes to after-sales support, FIG has a centralized ‘Customer Support Department’ to serve customers across India from its main office in Delhi through branch offices in Mumbai and Chennai.

0 notes

Text

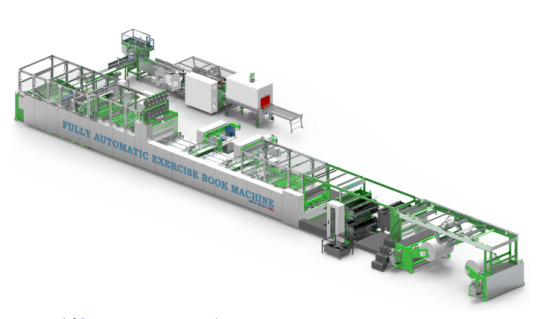

Line O Matic to show its innovations at Drupa 2024

http://indianprinterpublisher.com/wp-content/uploads/2024/04/Folio-Size-Sheeter-300x204.png

"At the drupa trade show, we are not just showcasing machines, we are showcasing a vision of the future in our largest stall to date having 760 sqm—a future where efficiency, sustainability, and innovation converge to create unparalleled value for our customers. We will be showcasing our flagship fully automatic Exercise Book machine accompanied by an array of machines — an inline Shrink-Wrapping machine (Bolt RB104 Max+ SWM 100), a Folio Size Sheeter (APEX RS165), an Automatic Binding machine for single ring books (Spiro B340 S) and automatic reel to reel Flexo Printing machine (STM 125)," said a company release.

"Join us at the drupa trade show, where innovation meets inspiration, excellence meets expectation, and Line O Matic Graphics Industries stands as a beacon of progress in an ever-evolving industry. Together, let us embark on a journey of discovery, collaboration, and transformation—one that will shape the future of print and packaging for generations to come," the release states.

0 notes

Text

CarryB Manufacturing Facility

Our expansive manufacturing facility in Udumalpet, Tamil Nadu, consists of five high- tech paper bag making machines, a 4 colour reel to reel printer and slitter re-winder that together manufacture Carry B’s range of products containing both virgin and recycled paper bags designed as per client specifications. It is of significance that Carry B’s custom printed bags are created on a high precision Flexo 4 colour printing platform, a fully automatic machine that enables more efficient adhesion and surficial finish on all types of customized bags.

Virgin paper is manufactured by chemically or mechanically separating cellulose fibres from wood or fibre crops and does not contain any recycled material. Recyclable paper bags on the other hand are either 100% recyclable including the handles, contains at least 40% post-consumer recycled paper content.

0 notes

Video

tumblr

Automatic leading edge two-colour flexo printing machine with slotting and stacking Automatic leading edge two-colour flexo printing machine with slotting and stacking

0 notes

Text

youtube

If you interested in this machine,please contact with us Sales:Arthas Lan Emai:[email protected] Mobile:+86 13695812095 Wechat ID:lan-tianyang Machine Usage:SBY-A-500 Model Automatic Flexo Printing Machine suit for print paper bag with handle and without handle.It with advanced auto feeding technology and fast color register technology. Customer can chose 2-4 Colors edition. https://www.berlan.en.alibaba.com/

1 note

·

View note

Text

youtube

If you interested in this machine,please contact with us Sales:Arthas Lan Emai:[email protected] Mobile:+86 13695812095 Wechat ID:lan-tianyang Machine Usage:SBY-A-500 Model Automatic Flexo Printing Machine suit for print paper bag with handle and without handle.It with advanced auto feeding technology and fast color register technology. Customer can chose 2-4 Colors edition.https://berlan.en.alibaba.com/

1 note

·

View note

Text

Flexo Printing UV LED Curing System

Bracket design, emitting window and optical power density can be customized.

Rich practical case experiences of customized solutions according to the printing machine models.

PLC+HMI, remote control available, real-time monitoring of temperature, current, voltage, abnormal working status automatic alarm.

Instant ON/OFF, no need to warm up.

Adopts modular constant current power supply drive. It is linked with the printing press speed signal, the power output is adjusted with the printing speed automatically .

Automatically control the water flow of a certain color unit to prevent condensation.

Height-LED looks forward to working with you.

WhatsApp: +8618924582621

Email: [email protected]

#uv#printing#uva#flexoprinting#varnish#leduv#uvled#arsoma#Mark Andy#Nilpeter#MPS#Gallus#label#sticker#tag

1 note

·

View note

Text

TR Group | Aseptic Brick Shape Carton Filling Machine

TR Group is a Group of Companies Led By Mr. Teja Ram Jat Who has 20 Years of Experience in Food and Beverage Industry. Group of Companies are TR International Ltd (Hongkong ). TR Global Services LLP, TR Packaging Machinery LLP, Jusica Agro Foods Pvt. Ltd. It's a Joint Venture Associa on with PLS Group.

We have over 250 Employees In India Including some Foreign Engineers which provides after Sale Service in India. We are Manufacturer of Turn Key Projects for Dairy, Beverages Liquor and Food Industry. We have Supplied over 195 Aseptic Machines in India and In other Countries Like Bhutan, Malaysia, Nepal and in African Countries.

"Our moto is “Best Service and Customer Satisfaction"

We are totally dedicated to provide best solution for the dairy and beverages industry along with our best service. We are the second biggest company in India who has supplied aseptic lines.

SHANGHAI PLS GROUP

PLS Group. is a high-tech enterprise jointly established by the team led by Mr. Jiang Weidong, SOFT BANK Investment Company. It’s a listed company from April 24th 2015, share code is 300442.

The company has gathered more than 110 talents who are professional in electromechanical integration, automatic control, mechanical design and food project etc. it’s a large scale company along with 2500 employees

TURN OVER/MARKETING/SERVICE BRANCH

Domestic – 20 local marketing/Service branches over the China

International Branches

India Marketing/Service Branch

Singapore Marketing /Service Branch

New Zealand Marketing /Service Branch

Turn Over – 300/Million USD of 2015

PARTNERS

Xpx Company

NEW UNIT OF PAPER PRODUCTION

New production printing lines are imported from italy U-Tech,

The imported line speed is 400 Meter/minute

Now total capacity is 8 billion pcs paper/yearly.

Old line are gravure printing.

The imported new line cost is 20 million USD.

Lamination line imported from Japan Sumitomo.

Now Totally we have three production line’s.

Flexo printing line is the fastest one in the lines.

We can deliver paper in 5 days only if have big qty.

#Aseptic brick filling machine#Aseptic brick shape carton filling machine#Tetrapak TBA 19 machine#aseptic milk pouch filling machine#Labelling machine#Shrink sleeve applicator

0 notes

Link

Flexo Printing Machine is the largest manufacturer in the global market. Krishna Engineering Works manufactures all types of Flexo Printing Machine, Flexographic Printing Machine, Flexo Printer, etc. We manufacture Flexo Printer in 4 colors, 6 colors, and 8 colors as per customer requirement. For more information:

Website: krishnaengineeringworks.com

Email: [email protected]

Contact Us: +91-7940085305

#Flexo Printing Machine#Flexographic Printing Machine#Automatic Flexo Printing Machine#Flexo Printer#Flexo Printing Machine Price#Flexographic Printing Press#Flexographic Machine#Flexo Printing Machine Manufacturers#High Speed Flexo Printing Machine

1 note

·

View note